5 Basic Principles of Safe Lifting

Understanding the 5 basic principles of safe lifting is essential for preventing injuries in the workplace. By following these principles, workers can reduce the risk of musculoskeletal disorders and other injuries.

Problems and Solutions

- Problem: Placing feet far from the object.

- Solution: Place feet close to the object to maintain balance.

- Problem: Not centering the body over the load.

- Solution: Center the body over the load to ensure stability.

- Problem: Bending at the waist instead of the knees.

- Solution: Bend at the knees to avoid straining the back.

- Problem: Poor hand-hold on the object.

- Solution: Get a good hand-hold to secure the load properly.

- Problem: Lifting with the back instead of the legs.

- Solution: Lift straight up, letting the legs do the work to protect the back.

- Problem: Twisting or making sudden movements while lifting.

- Solution: Avoid twisting and sudden movements while moving the load.

- Problem: Incorrectly setting down the load.

- Solution: Set the load down, letting the legs do the work to ensure safe placement.

Some additional lifting tips include:

5 basic principles of safe lifting.

• Clear a path of travel.

• Split the load into several small ones, employ the help of another work, or use

a mechanical aid if the load is too large or heavy.

• Push a load on a cart or dolly; do not pull it.

Is there a maximum allowable weight that an individual can lift?

OSHA does not have a regulation that addresses weight restrictions for manual lifting. OSHA has, however, used the NIOSH Lifting Equation to evaluate manual lifts during a workplace inspection. The NIOSH equation sets a fixed weight of 51 lbs. as the load constant (that is generally considered the maximum load nearly all healthy workers should be able to lift under optimal conditions.) However, the NIOSH equation also uses other factors such as height and angle of the lift, frequency of the lift, type of hand grip, and travel distance; these are all as important in assessing a lift as the weight of the object.

An alternative guide that focuses on male/female population percentages capable of performing a lift with certain characteristics, rather than on maximum weight limits, is the Liberty Mutual Material Handling tables. And Oregon OSHA has a tool that provides a fairly quick and user-friendly way to assess lifts.

Lifting Hazard Assessment Worksheet based on the 1991 NIOSH Revised Lifting

Equation. Beyond this information, employers may want to contact an ergonomist for guidance on the specific operation with respect to Musculoskeletal Disorders (MSDs)

What activities should be avoided to help prevent MSDs?

Here you can learn more about What activities should be avoided to help prevent MSDs? then follow the link for more details :https://jjkellercompliancenetwork.com/regsense/what-activities-should-be-avoided-to-help-prevent-msds

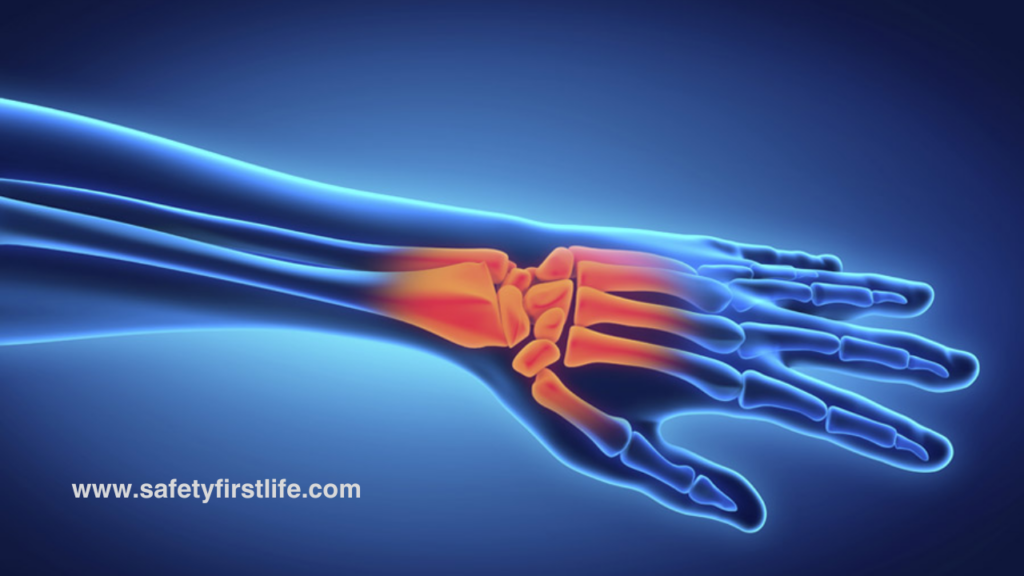

Prevention is the most important strategy for dealing with work-related musculoskeletal problems. Some postures to avoid include:

- Prolonged or repetitive flexion or extension of the wrist.

- Prolonged or repetitive bending at the waist.

- Prolonged standing or sitting without shifting position.

- Suspending an outstretched arm for extended periods of time.

- Holding or turning the head consistently to one side.

- Repeatedly or prolongedly holding any unnatural posture.

4o

Some motions which should be avoided include:

Manual Handling Technique

- Periods of rest not given for repeated motions.

- Little or no variation in repeated motions.

- Great force used in repeated motions.

- A body part rested or compressed on or against a surface.

- Heavy objects lifted far away from the body.

- Frequent reaching or work done above shoulder height.

What factors may contribute to symptoms of MSDs?

Each person has physical limits, or a “comfort zone,” of activities and work levels they

can tolerate without developing symptoms of MSDs. Some factors which may contribute to MSD symptoms include:

- Physically demanding work which employees are not accustomed to doing.

- Workers who are generally out of shape.

- Underlying arthritis.

- Diminished muscle strength or joint flexibility.

If you want detailed information on Effective safety controls then follow the link: https://safetyfirstlife.com/effective-safety-controls-to-prevent-excavation-incidents/

How can an employer determine if an MSDs is work-related?

Not all MSDs are work-related. MSDs can and do develop outside the workplace. The determination of whether any particular MSD is work-related may require the use of different approaches tailored to specific workplace conditions and exposures. Broadly speaking, establishing the work-relatedness of a specific case may include:

• Taking a careful history of the patient and the illness,

• Conducting a thorough medical examination.

to the MSD.

How can employers prevent MSDs in their workplace?

A good plan starts with employee involvement. Employers and employees can work together effectively to reduce work-related MSDs. Here are some ways:

Look at injury and illness records to find jobs where problems have occurred.

Talk with workers to identify specific tasks that contribute to pain and lost workdays.

Ask workers what changes they think will make a difference

Encourage workers to report MSD symptoms and establish a medical management system to detect problems early

Find ways to reduce repeated motions, forceful hand exertions, prolonged bending, or working above shoulder height

Reduce or eliminate vibration and sharp edges or handles that dig into the skin.

if you want to learn about crane safety then click on the link provided https://safetyfirstlife.com/what-is-a-crane/

• Rely on equipment (not backs) for heavy or repetitive lifting.

Simple solutions often work best. Workplace changes to reduce pain but cut the risk of disability need not cost a fortune. For example:

Change the height or orientation of the product, or use tools with handles designed so that workers won’t have to bend their wrists unnaturally to use the tool.

Additionally, offer workers involved in intensive keyboarding more frequent short breaks to rest muscles.

Furthermore, vary tasks of assembly line workers to avoid repeated stress for the same muscles

Finally, provide lifting equipment so workers won’t strain their backs.

Hi there! Would you mind if I share your blog with my twitter group?

There’s a lot of people that I think would really appreciate your content.

Please let me know. Thanks

This article is a great resource for understanding the fundamentals of safe lifting practices. By focusing on these 5 basic principles, readers can reduce the risk of injuries, improve workplace safety, and ensure efficient handling of loads. A must-read for anyone working with lifting equipment or manual handling tasks.

Howdy! I simply want to give you a big thumbs

up for your excellent info you’ve got right here on this post.

I’ll be returning to your web site for more soon.

Feel free to visit my site: nordvpn coupons inspiresensation, https://t.co/,