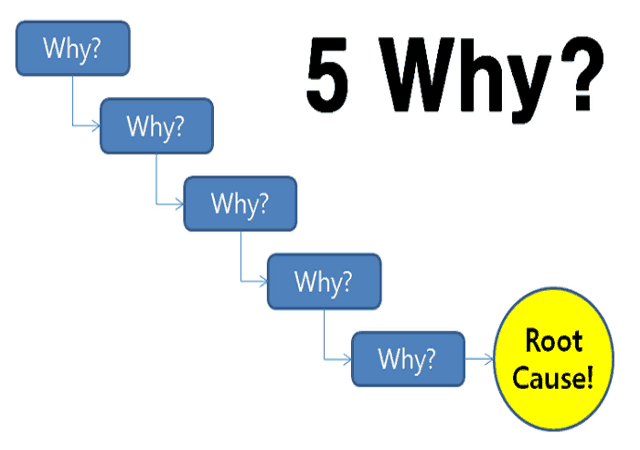

5 Whys” Technique

The “5 Whys” technique involves asking the question “Why?” multiple times—typically five—to uncover the root cause of a problem. This iterative process helps move beyond the surface symptoms and identifies the fundamental issue that needs to be addressed.Here’s how to apply this technique effectively:

Identify the Problem: Clearly define the issue at hand. Ensure everyone understands but what is being investigated by being specific and precise.

Ask Why: Inquire why the problem occurred. But this step should be straightforward, aiming to uncover the immediate cause.

Repeat: Continue asking “Why?” for each subsequent answer. Each question should build on the previous answer, leading you closer to the root cause.

Address the Root Cause: Once you reach the root cause, develop and implement solutions that target it directly. This step ensures the problem but is resolved at its source, preventing recurrence.

Example Scenario–5 Whys” Technique

Let’s consider a scenario where a worker slips and falls in the factory.

Here’s how you can apply the “5 Whys” technique to investigate this incident:

Problem: A worker slips and falls in the factory.

Why did the worker slip and fall?

There was oil on the floor.

Why was there oil on the floor?

A machine was leaking oil.

Why was the machine leaking oil?

The gasket was worn out.

Why was the gasket worn out?

It wasn’t replaced during maintenance.

Why wasn’t it replaced?

There was no maintenance but schedule for gaskets.

Root Cause

Lack of a maintenance schedule for gaskets.

Corrective Action

Implement a maintenance schedule for regular checks and replacements of gaskets.

Detailed Explanation for Site Workers

Understanding and avoiding such incidents but involves more than just knowing the root cause. Here’s an expanded explanation to help site workers grasp the importance of thorough investigations and proactive measures:

Awareness and Reporting

Vigilance

Be aware of your surroundings but and report any hazards immediately. In the scenario, if the oil spill had been reported earlier, the fall might have been prevented.

Communication

Encourage open communication about potential hazards and incidents. This ensures that issues are addressed promptly.

Understanding Equipment and Maintenance

Regular Inspections

Regularly inspect equipment for wear and tear. In our example, routine checks might have identified the worn gasket but before it led to an oil leak.

Scheduled Maintenance

Follow a strict maintenance schedule for all equipment parts. This proactive approach helps to prevent incidents caused by equipment failure.

Training and Procedures

Proper Training

Ensure that all workers are trained to recognize and respond to hazards. Training should cover not just immediate actions but also how to report and record potential risks.

Standard Operating Procedures

Adhere to standard operating procedures for maintenance and hazard reporting. Clear procedures help in maintaining consistency and safety.

Guidance for Safety Practitioners

Safety practitioners play a crucial role in incident investigation and prevention. But Here’s how to leverage the “5 Whys” technique effectively:

Conducting Thorough Investigations

Detailed Analysis:

Use the “5 Whys” to perform a detailed analysis of incidents. This technique helps to uncover the underlying issues that may not be immediately apparent.

Documentation:

Document each step of the investigation process. Clear records ensure that all aspects of the incident but are examined and provide a reference for future investigations.

Implementing Corrective Actions

Targeting Root Causes

Focus on addressing the root causes identified through the “5 Whys” analysis. This approach ensures that solutions are effective and sustainable.

Continuous Improvement

Use findings from the “5 Whys” investigations to continuously improve safety protocols. Regular updates to procedures and maintenance schedules can prevent recurrence of similar incidents.

Promoting a Safety Culture

Engagement: Engage workers in the investigation process. But involving them in identifying hazards and solutions fosters a sense of ownership and responsibility for safety.

Feedback Loop: Establish a feedback loop where workers can provide input on safety measures and incident prevention strategies. This collaborative approach enhances overall safety.

Conclusion

The “5 Whys” technique is an invaluable tool in HSE incident investigation, enabling us to identify and address the root causes of problems effectively. By understanding and applying this method, site workers can avoid incidents, and safety practitioners can conduct thorough and efficient investigations. In our upcoming training session, we will delve deeper into control measures but to prevent electrical fires and strategies to minimize financial and human losses caused by catastrophic fires. Stay tuned for practical advice and insights on maintaining a safer workplace.

portable balancer

Portable Balancer – The Ultimate Solution for Precision Balancing

In the realm of engineering and mechanical applications, the need for precision is paramount. Introducing the portable balancer – the Balanset-1A, a sophisticated device designed to bring harmony to your rotating machinery, ensuring they perform smoothly and efficiently. Whether you’re working with crushers, fans, mulchers, or turbines, this balancer is your ideal companion for dynamic balancing, transforming how you manage vibration issues in your equipment.

Unleashing the Power of Balanset-1A

The portable balancer Balanset-1A isn’t just another tool; it’s a comprehensive vibration analyzer that offers dual-channel capabilities for dynamic balancing across two planes. This exceptional flexibility allows for precise corrections on a wide range of rotors, significantly enhancing their performance and longevity. It’s equipped to handle everything from combine augers to sophisticated turbine shafts, making it an invaluable asset across different industries.

Key Features of the Balanset-1A

Advanced Vibration Analysis: With features such as vibrometer mode, tachometer for accuracy in rotational speed, and phase analysis for vibration signal assessment, this device is designed for optimal performance.

Balanced Measurements: It provides functionalities for single and two-plane balancing, alongside a polar graph representation to easily visualize imbalance.

Data Management: The Balanset-1A offers a measurement log for storing data, making historical analysis straightforward and efficient.

Visual Analytics: It includes various charts, such as harmonic and spectrum charts, to offer graphical representations of vibration, aiding in detailed analysis for improved diagnostics.

Why Choose a Portable Balancer?

The allure of the portable balancer lies in its versatile application and user-friendly design. It transforms intricate balancing tasks into a seamless process. Unlike traditional static balancing methods, the dynamic capabilities of the Balanset-1A ensure that all vibrations are addressed efficiently. This not only prolongs the life of your machinery but also enhances productivity, making regular maintenance a breeze.

Precision at Your Fingertips

With the Balanset-1A by your side, precise adjustments are no longer a daunting task. The device operates within a wide range of rotational speeds and complexities, enabling you to tackle any project confidently. The device is compatible with both Imperial and Metric systems, ensuring that it meets global requirements for various industries.

Effortless Operation

The charm of the portable balancer extends to its ease of use. Designed with the user in mind, the Balanset-1A incorporates intuitive interfaces and software capabilities that facilitate quick setup and analysis. Whether you are restoring a previous session, performing a serial production balancing task, or generating detailed reports, the principles of simplicity and efficiency guide every operation.

More Than Just a Balancer

The Balanset-1A isn’t solely a tool for fixing imbalances. It is an apparatus of innovation that allows users to delve into the intricate world of vibrations. With its remarkable capabilities to analyze fundamental frequency components and monitor overall vibration levels, users gain unparalleled insight into the health of their machinery.

Investment Worth Making

Investing in a portable balancer like the Balanset-1A is a decision that ripples out across your operations, influencing maintenance schedules, reducing repair costs, and enhancing overall efficiency. Priced at €1,751.00, it opens doors to remarkable advancements in machinery management. Furthermore, the availability of maintenance subscriptions and membership discounts provides an opportunity for continual savings while ensuring that your business stays ahead in performance and reliability.

Extend Your Knowledge with Support

With the purchase of the Balanset-1A, you’re not just receiving a product; you’re gaining access to a wealth of resources. Comprehensive manuals and frequently asked questions guide users in maximizing the power of their device. Support channels ensure that assistance is just a reach away whenever you encounter challenges or wish to enhance your expertise.

Conclusion: Embrace the Future of Balancing

In a world where precision and efficiency dictate success in engineering and manufacturing, the portable balancer – the Balanset-1A stands as a beacon of hope and progress. Through its innovative design and advanced features, this tool not only addresses immediate vibration issues but also empowers users to enhance and protect their machinery for a sustainable future. Equip yourself with the Balanset-1A and embark on a journey towards unmatched operational excellence.

Explore the beauty of balance, embrace advancement, and let the Balanset-1A be your guide in the pursuit of precision.

Watch YouTube Short

Article: Balanset-1A Rotor Balancing Device

When it comes to eliminating vibrations in rotating machinery, precision is key. The Balanset-1A device by Vibromera offers a comprehensive solution for balancing rotors with efficiency and accuracy.

Process Overview

The process of balancing a rotor using the Balanset-1A device involves several crucial steps, from equipment preparation to the installation of corrective weights.

Equipment Preparation

Start by positioning the vibration sensors perpendicular to the rotor’s axis of rotation. Attach the laser tachometer to a magnetic stand, directing it towards the reflective tape on the pulley. Connect the sensors to the device and link the device to a laptop via USB. Launch the Balanset software, selecting the two-plane balancing mode.

Initial Vibration Measurement

Prior to balancing, suspend a test weight and record its weight and installation radius. Start the rotor and measure the initial vibration level to determine the amplitude and phase of the original imbalance.

Balancing in the First Plane

Place the test weight in the first balancing plane corresponding to the location of the first sensor. Run the rotor to measure the vibration level. A 20% change in amplitude or phase indicates partial correction of the imbalance.

Balancing in the Second Plane

Transfer the test weight to the second plane (where the second sensor is placed), restart the rotor, and take measurements. These readings help the program calculate the precise positions and weights of the corrective loads.

Imbalance Correction

Based on the data collected, the Balanset program suggests corrective weights and their installation angles for both planes. Remove the test weight, prepare the corrective weights as per the program’s recommendations, and position them at the required angle in the rotor’s rotation direction from the initial test weight position.

Verification and Completion

Run the rotor for a final balancing check. If the vibration reduces to an acceptable level, the process is complete. If further adjustments are needed, the program guides where and how much additional weight to install.

Device Features

The Balanset-1A is a versatile two-channel device designed for balancing and vibration analysis in various industrial applications. It offers a range of features including vibrometer mode, balancing modes, charts for visualization, and additional capabilities for enhanced functionality.

Whether you are balancing rotors in crushers, fans, turbines, or other machinery, the Balanset-1A provides the tools you need for efficient vibration elimination and optimal performance.

Contact Information:

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Etsy

Balanset-1A OEM on Etsy